Advanced Welding Techniques- Current Trends and Future

To meet weight, quality, and cost targets, it is essential to design, develop, and manufacture optimal, cost- effective welded structures that take into consideration material, process, and dimensioning procedures. For effective design, a weld designer must have a comprehensive grasp of welding basics, associated metallurgy, and fabrication and characterization processes. Advanced Welding Techniques highlights breakthroughs in advances in welding methods and provides readers with the ability to accurately identify the appropriate welding processes and optimal improvement methods for intended applications. It offers comprehensive guidance on welding design to ensure readers are equipped to provide solutions to any technical malfunctions they may encounter, including:

Supplies essential stepwise knowledge on design for welding, starting with the fundamentals to the complex Covers role of filler metals and parameters on welding performance, emerging and advanced welding techniques, and advantages and limitations of various methods Discusses integration of additive manufacturing and welding Contains practical applications Considers challenges and future scope for further research as well as future challenges This book offers students, academics, researchers, scientists, engineers, and industry experts a comprehensive overview of the most recent breakthroughs in advanced welding methods and their applications to joining various metals and their alloys.

Product details

Half Title

Title Page

Copyright Page

Table of Contents

Preface

List of Contributors

1 Welding Scope, Application, and Opportunities

1. Introduction

2. Classification of Welding Technology

2.1. Welding Process Based On Heat Source

2.1.1. Shielded Arc Welding

2.1.2. Gas Tungsten Arc Welding

2.1.3. Gas Metal Arc Welding

2.1.4. Resistance Welding

2.1.5. Oxy-Acetylene

2.1.6. Explosive Welding

2.1.7. Thermite Welding

2.1.8. Laser Beam Welding

2.1.9. Electron Beam Welding

2.2. Based On Pressure Applied

2.2.1. Friction Stir Welding

2.2.2. Friction Welding

2.2.3. Ultrasonic Welding

3. Scope and Application of Welding

4. Future Opportunity in Welding

5. Conclusion

References

2 Various Advanced Welding Methods: A Brief Overview

1. Introduction

2. Various Advanced Welding

2.1. Laser Welding

2.1.1. Working Principle

2.1.2. Modes of Operation

2.1.3. Types of Laser

2.1.4. Advantages and Disadvantages of Laser Welding

2.1.5. Applications

2.1.6. Common Defects in Laser Welding and Its Remedies [3]

2.2. Electron Beam Welding

2.2.1. Advantages

2.2.2. Disadvantages

2.2.3. Applications

2.3. Friction Stir Welding

2.3.1. Processing Parameters of FSW

2.3.2. Applications

2.4. Robotic Welding

2.4.1. Advantages and Disadvantages

2.5. Hybrid Welding

2.6. Ultrasonic Welding

2.7. Explosive Welding

2.7.1. Working Principle

2.7.2. Disadvantages

2.7.3. Applications

3. Summary

References

3 Heat Generation and Physics of the Arc Welding Process

1. Introduction

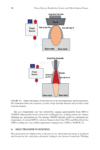

1.1. Electric Arc Generation

1.2. Plasma Formation

1.3. Heat Generation

1.4. Excitation and Ionization

1.5. Melting and Weld Pool Formation

1.6. Heat Distribution and Transfer

1.7. Shielding Gas

1.8. Electrode Contribution

2. Arc Initiation in Welding

2.1. Touch Start Method

2.2. Field Start Method

2.3. Scratch Start Method

2.4. Pilot Arc

2.5. Plasma Arc Torch

2.6. Electron Beam Welding

3. Emission of Free Electrons

4. Maintenance of Arc in Welding

4.1. Arc Length Control

4.2. Welding Current and Voltage Control

4.3. Electrode Position and Angle

4.4. Electrode Consumption

4.5. Shielding Gas and Flux

4.6. Electrode and Torch Cooling

4.7. Operator Skill

4.8. Arc Control Technology

5. Method Involving Low Ionization Potential Elements

6. Approach Utilizing Low Power Factor

7. Welding Arc Characteristics

7.1. Drooping Characteristic Zone

7.2. Flat Characteristic Zone

7.3. Rising Characteristic Zone

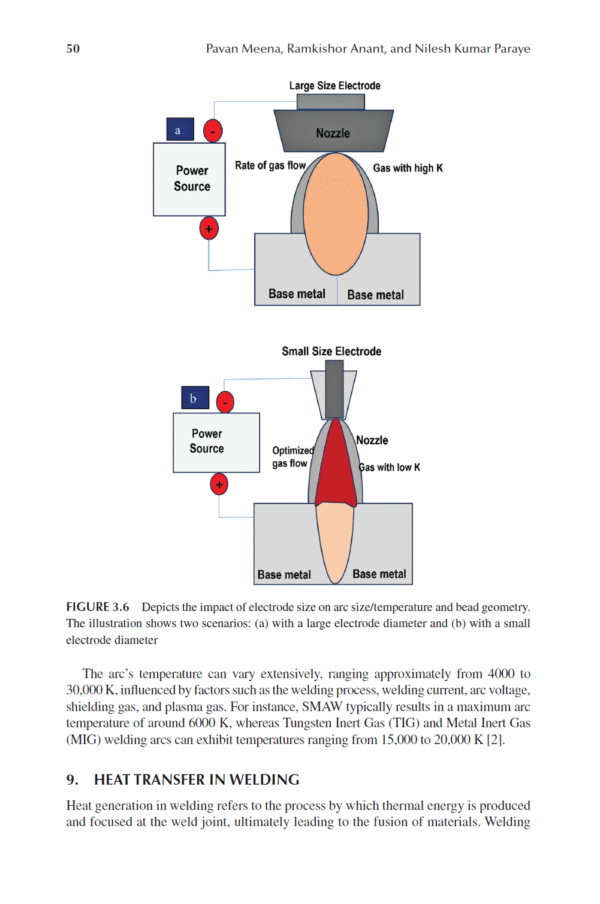

8. Arc Temperature Considerations

9. Heat Transfer in Welding

9.1. Heat Conduction Equation

9.2. Heat Transfer By Convection

9.3. Radiative Heat Transfer

10. Metal Transfer Processes

11. Heat Transfer Through Pulsed Gas Metal Arc Welding (P-GMAW)

11.1. Pulsing Frequency and Duty Cycle

11.2. Peak Current (I p )

11.3. Base Current (I b )

11.4. Pulse Frequency (F)

11.5. Pulse Duration (T p )

11.6. Droplet Detachment Mechanism

11.7. Thermal Behavior of Weld

References

4 Defects Associated With Welding Techniques and Their Detection Methods

1. Introduction

2. Types of Welding Defects

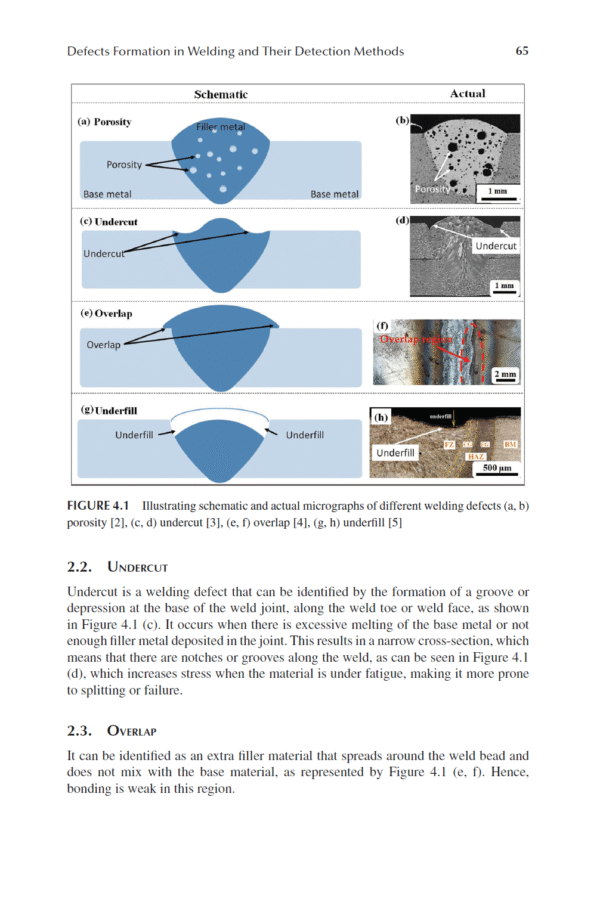

2.1. Porosity

2.2. Undercut

2.3. Overlap

2.4. Underfill

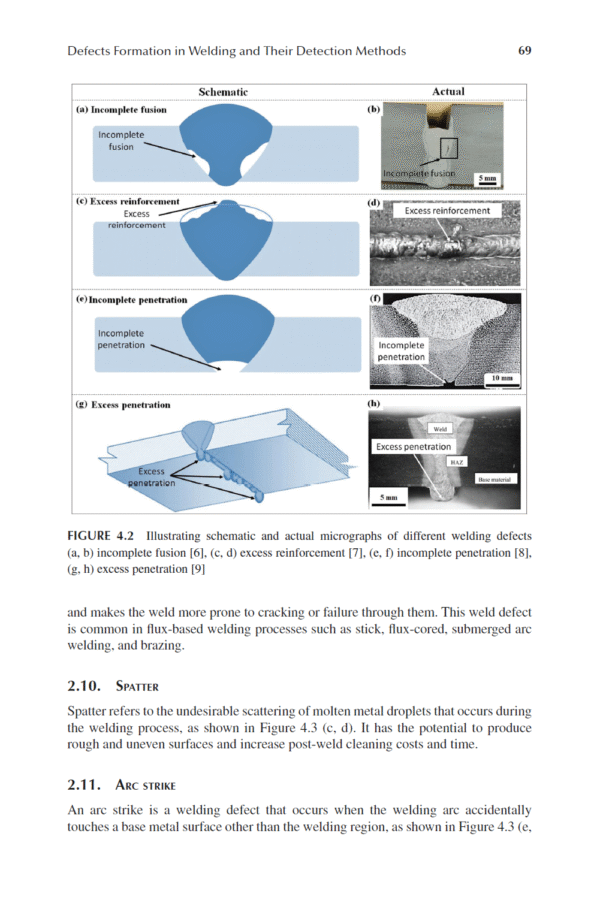

2.5. Incomplete Fusion

2.6. Excess Reinforcement

2.7. Incomplete Penetration

2.8. Excess Penetration

2.9. Slag Inclusion

2.10. Spatter

2.11. Arc Strike

2.12. Burn-Through

2.13. Distortion

2.14. Misalignment

2.15. Welding Cracks

2.15.1. Crater Cracks

2.15.2. Hot Cracks

2.15.3. Cold Cracks

2.16. Improper Electrode Selection

3. Detection Methods

3.1. Visual Inspection

3.2. Dye Penetrant Test

3.3. Magnetic Particle Testing

3.4. Acoustic Emission Testing

3.5. Radiography Testing

3.6. Ultrasonic Testing

3.7. Eddy Current Testing

3.8. Infrared Thermography

4. Summary

References

5 Role of Filler Materials On Welding Performance

1. Introduction

2. Selection of Filler Metal

2.1. Metallurgical Compatibility

2.2. Physical Properties

2.3. Corrosion Properties

3. Effect of Filler Material On the Galvanic Corrosion

4. Effect of Filler Material On Liquation Cracking

5. Filler Metal Effect On Fusion Region

5.1. Case Study 1

5.2. Case Study 2

6. Dilution and Its Effect

7. Control of Solidification Cracking With Filler Metal Composition

7.1. Aluminium Alloy

7.2. Carbon and Low Alloy Steel

8. Prediction of Weld Metal Constitution

8.1. Case Study—selecting the Correct Filler Metal Based On Constitution Diagram

References

6 Effect of Welding Parameters On Structure-Property Correlation

1. Introduction

2. Influence of Welding Parameters On Similar and Dissimilar Welding of SS

2.1. Similar Welding of SSs

2.1.1. Austenitic Stainless Steel (ASS)

2.1.2. Ferritic Stainless Steel (FSS)

2.1.3. Duplex Stainless Steel (DSS)

2.1.4. Martensitic Stainless Steel (MSS)

2.2. Dissimilar Welding of SSs

2.2.1. Austenitic-Austenitic SS

2.2.2. Austenitic-Duplex SS

2.2.3. Austenitic-Ferritic SS

2.2.4. Duplex-Martensitic SS

3. Conclusion

References

7 Tungsten and Metal Inert Gas Welding: Automation in Welding

1. Introduction

1.1. Tungsten Inert Gas (TIG) Welding

1.2. Metal Inert Gas (MIG) Welding

2. TIG Welding for Aluminium

3. MIG Welding for Aluminium

4. Automation of Welding Processes

5. Summary

References

8 Friction Stir Welding and Design

1. Introduction

2. Friction Stir Welding Design and Parameters

3. Similar and Dissimilar Metal Joining

4. Numerical Techniques in FSW

5. Possible Future Work Avenues

6. Summary

References

9 Laser Beam Welding: Opportunity and Challenges

1. Introduction

2. Laser Beam Welding for Material Joining

2.1. Conduction Mode

2.2. Keyhole Mode

3. Role of Laser Beam Welding Process Parameters

4. Challenges in Laser Beam Welding

4.1. Joining of Dissimilar Materials

4.2. Common Metallurgical Defects During Laser Welding

4.3. Development of Residual Stress

4.4. Laser Sensitivity to Materials

4.5. Safety Concern

4.6. High-Cost Concern

5. Dissimilar Welding: Emerging Developments

5.1. Emerging Advancements On the Difficulties of Welding Steel With Other Alloys (Al, Mg, Ti)

6. Applications of Laser Beam Welding

7. Conclusions

References

10 Hybrid Welding Processes: Challenges and Future Perspective

1. Introduction

2. Hybrid Laser-Arc Welding

2.1. Interaction Between Laser Beam and Arc

2.2. Hybrid Laser-Arc Welding Process Parameters for Proper Joint Quality

2.2.1. Energy Input

2.2.2. Welding Speed

2.2.3. Relative Position of the Laser and the Arc Torch Along the Welding Direction

2.2.4. Focal Point Position

2.2.5. Angle of Electrode

2.2.6. Joint Gap (Or Gap-Bridging)

2.3. Root Hump Formation

2.4. Microstructure-Mechanical Property Relationship

3. Hybrid Laser-Friction Stir Welding

4. Hybrid Welding Areas of Applications

5. Summary

References

11 Additive Manufacturing Integration With Welding

1. Introduction

1.1. Background

1.2. Objectives of Integration

2. Overview of AM Processes

2.1. AM Techniques

2.2. AM Materials and Material Compatibility With Welding Processes

3. Welding Processes

3.1. Traditional Welding Techniques

3.1.1. GTAW-Based WAAM

3.1.2. PAW-Based WAAM

3.1.3. GMAW-Based WAAM

3.1.4. Cold Metal Transfer (CMT)

3.1.5. Tandem GMAW

3.2. Welding Parameters

3.3. Advanced Welding Techniques

4. Challenges and Solutions

4.1. Managing Thermal Stresses During Integration

4.2. Heat-Affected Zones and Distortion Control

4.3. Matching AM and Welding Materials

4.4. Optimizing Design

5. Case Studies and Applications

5.1. Aerospace Industry

5.2. Medical Devices

5.3. Automotive Sector

6. Future Trends and Research Directions

6.1. Emerging Technologies

6.2. Industry 4.0 Integration

7. Conclusion

7.1. Summary of Key Findings

7.2. Recommendations for Future Research

References

12 Current Scenario, Future Scope, and Challenges in Welding

1. Introduction

2. Types of Welding Techniques

2.1. Beam Welding (LBW, LAHW, EBW)

2.2. Arc Welding (PAW, CMTW, X-TIGW, X-MIGW)

2.3. Friction Welding (LFW, OFW, FSW, FSSW, FSAM)

2.4. Pulse Welding (USW, MPW)

2.5. Under Welding (X-UWW, UVW, UPW)

2.6. Material-Specific Welding (NW, DMW, GW)

2.7. Smart Welding (SW)

2.8. Hybrid Welding (X-HW)

3. Current Scenario of Welding

3.1. Use of Automation in Welding

3.1.1. Advantages and Disadvantages of Automation

3.2. New Materials Processes in Welding

3.2.1. Advancements in Welding Processes

3.2.2. Regulated Metal Deposition (RMD)

3.2.3. Spray Transfer

3.2.4. Surface Tension Transfer

3.2.5. Nanometal Matrix Composite (MMC) Powders

3.3. Environmental Impact of Welding

3.3.1. Pollution Generated By Welding

3.3.2. Solutions Reduce Environmental Impact

4. Future Scope of Welding

4.1. Role of Digitalization in Welding

4.1.1. Integration of AI

4.1.2. Implementation of IoT

4.2. Application of Welding in Emerging Industries

4.2.1. Aerospace, Defense, and Automotive Industry

4.2.2. Medical Industry

4.3. Advancement in Welding Technology

4.3.1. Robotics and Automation

4.3.2. 3D Printing in Welding

5. Challenges in Welding

5.1. Skilled Workforce Shortage

5.1.1. Encouraging Diversity in the Welding Industry

5.2. Safety Risks and Hazards

5.2.1. Measures to Promote Occupational Health

5.2.2. Welding Safety

5.2.3. Importance of Proper Education, Training, and Equipment

5.3. Cost Consideration

5.3.1. Impact of Welding On Project Costs

5.3.2. Cost-Effective Solutions for Welding Projects

6. Conclusion

References

Index

Shipping and Returns

Shipping cost is based on weight. Just add products to your cart and use the Shipping Calculator to see the shipping price.

We want you to be 100% satisfied with your purchase. Items can be returned or exchanged within 30 days of delivery.

There are no question found.

Rating & Review

There are no reviews yet.